Mitigating Risks in the Oclacitinib Maleate API Supply Chain

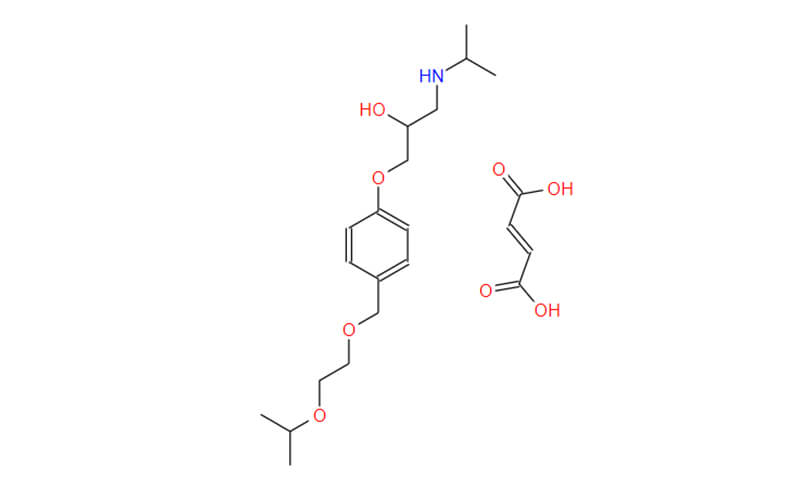

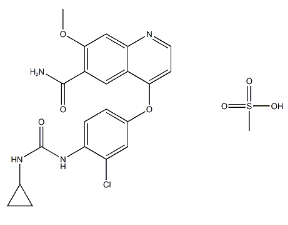

Growing demand for oclacitinib maleate API, a key ingredient in veterinary medicines for the treatment of canine atopic dermatitis, highlights the need for a safe and reliable supply chain. However, ensuring consistent quality and mitigating potential risks throughout the supply chain can be a challenge for pharmaceutical companies and manufacturers.

This article explores the key risks associated with the oclacitinib maleate API supply chain and provides actionable strategies to minimize these risks. We will also discuss how working with a reliable oclacitinib maleate API supplier like Aoki can significantly reduce your risk profile.

Key Risks in the Oclacitinib Maleate API Supply Chain

Several factors can disrupt the smooth flow and quality of Oclacitinib Maleate API within the supply chain:

- Raw Material Sourcing: Dependence on unreliable raw material suppliers can lead to inconsistent quality or even shortages of essential components for Oclacitinib Maleate API production. Inconsistent quality of raw materials can affect the final purity and efficacy of the API. Shortages can cause production delays and hinder your ability to meet market demands.

- Manufacturing Issues: Substandard manufacturing practices or a lack of compliance with cGMP (Current Good Manufacturing Practice) regulations can compromise the quality and purity of the final API. Substandard manufacturing practices can lead to contamination, inconsistencies in potency, or the presence of impurities in the Oclacitinib Maleate API. This can jeopardize the safety and efficacy of the finished medication and potentially lead to regulatory issues.

- Transportation and Storage: Improper handling or inadequate storage conditions during transportation and warehousing can lead to API degradation, impacting the efficacy and safety of the finished medication.

- Counterfeiting and Adulteration: The growing demand for Oclacitinib Maleate API creates a risk of encountering fraudulent suppliers offering low-quality or adulterated products.

By understanding these key risks and implementing proactive mitigation strategies, you can safeguard the quality and integrity of your Oclacitinib Maleate API supply chain. Partnering with a reliable API supplier like Qingmu can further strengthen your risk management efforts.

Strategies for Mitigating Oclacitinib Maleate API Supply Chain Risks

To effectively manage risks within the supply chain of Oclacitinib Maleate API, a multifaceted strategy is necessary, focusing on bolstering resilience and adaptability. Below are comprehensive approaches:

- Strengthened Quality Control: Stringent quality control measures need implementation at all stages of production and distribution. This encompasses rigorous testing protocols to guarantee the purity, potency, and stability of Oclacitinib Maleate API. Routine inspections and audits aid in promptly identifying and rectifying any deviations from quality standards.

- Supplier Diversification: Dependence on a single supplier presents a significant vulnerability to the supply chain. By diversifying the supplier base, pharmaceutical companies can spread their risk and minimize the impact of disruptions. Collaborating with multiple suppliers allows for greater flexibility in sourcing, ensuring a consistent supply of Oclacitinib Maleate API even amidst unforeseen events affecting one supplier.

- Transparency and Traceability: Integration of advanced tracking and monitoring technologies enhances transparency and traceability throughout the supply chain. Real-time data analytics enable stakeholders to pinpoint potential bottlenecks, monitor inventory levels, and track the movement of Oclacitinib Maleate API from manufacturer to end-user. This proactive approach facilitates early detection of disruptions, enabling timely intervention and mitigation measures.

- Risk Assessment and Preparedness Planning: Regular risk assessments are vital for identifying vulnerabilities within the supply chain. By anticipating potential risks such as natural disasters, geopolitical instability, or regulatory changes, pharmaceutical companies can develop robust contingency plans. These plans should delineate alternative sourcing options, emergency response protocols, and communication strategies to minimize disruptions and ensure continuity of supply.

- Collaborative Engagements: Building collaborative partnerships with key stakeholders, including suppliers, distributors, and logistics providers, promotes a collective approach to risk management. By sharing information, resources, and best practices, stakeholders can collectively tackle challenges and fortify the resilience of the supply chain. Open channels of communication facilitate swift issue resolution and proactive risk mitigation efforts.

Adopting these strategies enables pharmaceutical companies to fortify the resilience, flexibility, and dependability of the Oclacitinib Maleate API supply chain. Proactive risk management practices empower stakeholders to anticipate and address potential disruptions, guaranteeing uninterrupted access to this crucial medication for treating canine atopic dermatitis.

The Role of a Reliable Oclacitinib Maleate API Supplier

In today’s competitive landscape of veterinary pharmaceuticals, aligning with a trusted Oclacitinib Maleate API provider such as Qingmu presents notable benefits that extend beyond mere ingredient provision. Recognizing the paramount importance of a secure and transparent supply chain for Oclacitinib-based medication development, Qingmu offers valuable contributions to your endeavors:

- Quality stands as the cornerstone of Qingmu’s operations. Our advanced facilities strictly adhere to cGMP regulations, ensuring that every facet of the Oclacitinib Maleate API production process meets rigorous quality benchmarks. We implement meticulous multi-stage quality control protocols, spanning from raw material scrutiny to final product analysis. This steadfast commitment ensures consistent levels of potency, purity, and safety across each batch of Oclacitinib Maleate API we manufacture.

- Fostering trust with our partners is fundamental at Qingmu. We nurture longstanding associations with reputable suppliers of raw materials, guaranteeing a steady supply of top-notch ingredients for Oclacitinib Maleate API production. Emphasizing open dialogue, we regularly furnish updates on production procedures, regulatory shifts, and any potential supply chain challenges. This transparency facilitates proactive planning and mitigates the risk of disruptions.

- Our team possesses extensive expertise in the regulatory landscape governing Oclacitinib Maleate API across key markets such as the US, EU, and China. Remaining abreast of evolving regulations, we ensure that our API aligns with all requisite quality and safety standards for your target markets. This proficiency expedites your product registration endeavors and facilitates expedited market entry for your Oclacitinib-based veterinary formulations.

By developing cooperation with Qingmu, you gain a dependable supplier dedicated to providing high-quality Oclacitinib Maleate API, supported by rigorous quality assurance methods and a commitment to open communication. We provide the certainty of a secure and transparent supply chain, helping you to focus on developing and delivering effective solutions for canine atopic dermatitis.

Conclusion

Mitigating hazards in the Oclacitinib Maleate API supply chain is critical to ensure the constant quality and safety of canine atopic dermatitis treatments. By applying the tactics discussed above and collaborating with a reputable Oclacitinib Maleate API supplier, such as Qingmu, you can reduce supply chain disruptions and concentrate on developing and delivering excellent pet care solutions.