Managing the Product Life Cycle: Firocoxib API and Formulations

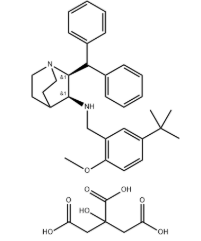

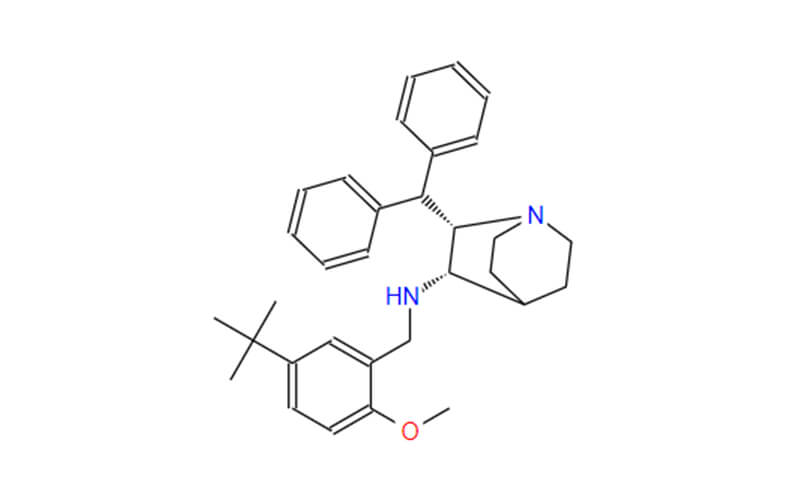

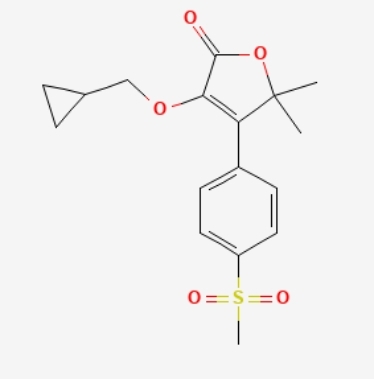

Firocoxib, a non-steroidal anti-inflammatory drug (NSAID) for animals, plays a vital role in veterinary medicine. Like any pharmaceutical product, firocoxib’s success relies heavily on effective product life cycle management (PLCM).

Firocoxib was first approved by the FDA for use in dogs on July 21, 2004. It’s sold under the brand name Previcox. [FDA Approves the First Generic Firocoxib Chewable Tablets for Dogs]

Firocoxib for horses received FDA approval later, on July 24, 2016. This version is sold as Equioxx Tablets. [FDA Approves the First Generic Firocoxib Tablets for Horses]

Stages of the Product Life Cycle of Firocoxib API

Like any pharmaceutical product, firocoxib goes through a well-defined life cycle, encompassing several stages from initial research to post-market monitoring. Let’s delve into the key stages of the firocoxib API (Active Pharmaceutical Ingredient) product life cycle:

1. Research and Development (R&D):

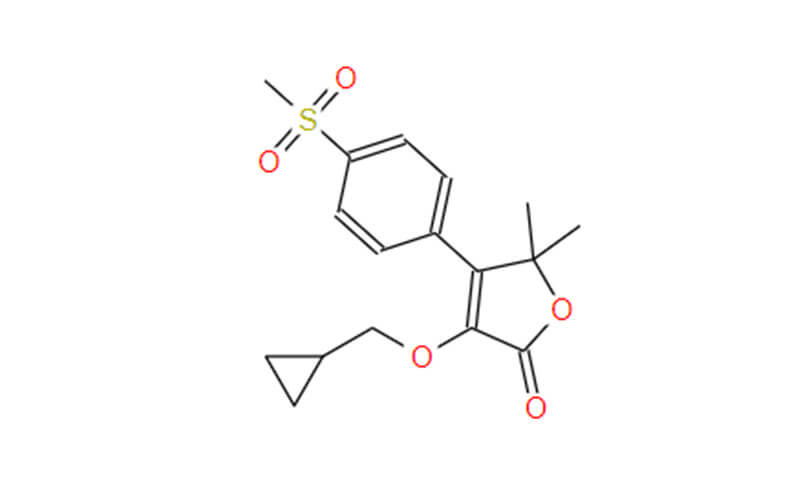

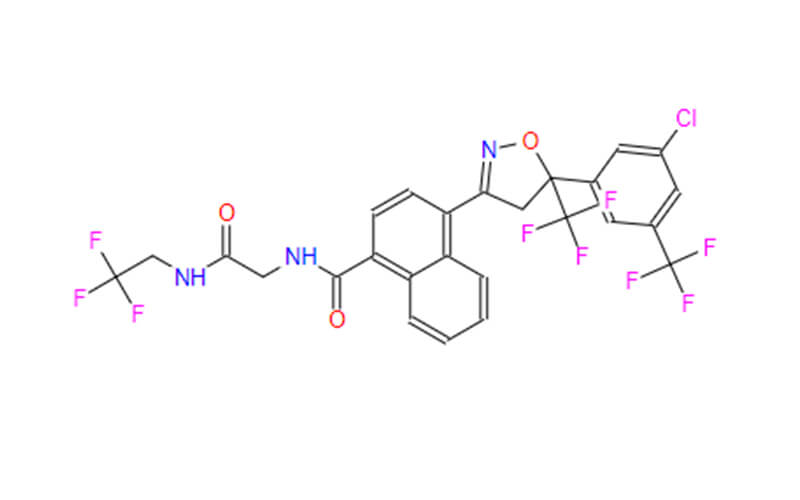

This initial stage involves the discovery and development of the firocoxib molecule. Scientists research the properties of different compounds, searching for those with potential therapeutic effects. Once a promising candidate is identified, extensive testing is conducted in laboratories to determine its safety and efficacy. This phase also involves formulation development, where scientists create a stable and deliverable form of the drug, such as a powder or liquid, suitable for further manufacturing into final dosage forms like tablets or chewable treats.

2. Pre-clinical Trials:

After successful laboratory testing, firocoxib undergoes pre-clinical trials. In this stage, the drug is administered to animals, typically rodents or canines, in controlled settings. These trials aim to assess the drug’s safety profile, identify potential side effects, and determine its pharmacokinetics (how the body absorbs, distributes, metabolizes, and excretes the drug).

3. Clinical Trials:

Assuming pre-clinical trials are successful, firocoxib then progresses to clinical trials. Here, the drug is tested in target animal populations, often dogs or cats with specific pain or inflammatory conditions. Clinical trials are typically phased, with Phase I focusing on safety in a small number of animals, Phase II evaluating efficacy in a larger group, and Phase III involving large-scale trials to confirm effectiveness and gather further safety data. Stringent regulations govern clinical trials to ensure the safety and well-being of the animals involved.

4. Regulatory Approval:

After successful clinical trials, the manufacturer submits a New Animal Drug Application (NADA) to a regulatory agency like the U.S. Food and Drug Administration (FDA). This application includes extensive data from the pre-clinical and clinical trials, demonstrating the drug’s safety, efficacy, and quality. The regulatory agency meticulously reviews the data before granting approval for the drug to be marketed and used in veterinary medicine.

5. Manufacturing and Distribution:

Once regulatory approval is obtained, firocoxib API production can begin in large-scale manufacturing facilities. Strict quality control measures are in place throughout the manufacturing process to ensure the consistency and purity of the API. The manufactured firocoxib API is then distributed to pharmaceutical companies that will formulate it into final dosage forms for veterinary use.

6. Post-Marketing Surveillance:

Even after reaching the market, firocoxib continues to be monitored. Veterinarians and animal owners are encouraged to report any adverse drug reactions experienced by animals taking firocoxib. Regulatory agencies also collect and analyze this data to identify any potential safety concerns and ensure the ongoing safety and efficacy of the drug.

This comprehensive life cycle ensures that firocoxib, like any medication used in veterinary medicine, undergoes rigorous testing and evaluation before being made available to treat animals in need.

Key Considerations for Each Stage

Here’s a more detailed breakdown of the key considerations for each stage in the Firocoxib API product lifecycle:

1. Research & Development (R&D):

- Target Identification: Thoroughly understand the biological mechanisms of pain and inflammation in dogs and horses. Identify Firocoxib’s specific target (e.g., COX-2 enzyme) and how it achieves its therapeutic effect.

- Pre-clinical Trials: Conduct in-vitro and in-vivo studies to assess Firocoxib’s safety and efficacy in cell cultures and animal models (typically rats or mice). These studies should establish a dose range for further clinical trials.

- Formulation Development: Develop stable and effective formulations suitable for the target animal species. This may involve different dosage forms (tablets, chewables, injectables) with appropriate excipients (inactive ingredients) for optimal delivery and absorption.

- Intellectual Property (IP) Protection: Secure patents for Firocoxib’s structure, formulation, and manufacturing processes to protect your investment and market exclusivity.

- Manufacturing Partner Selection: Identify reliable Contract Manufacturing Organizations (CMOs) with expertise in producing sterile or non-sterile APIs adhering to cGMP (Current Good Manufacturing Practices) standards.

2. Regulatory Approval:

- Clinical Trial Design: Develop a well-designed clinical trial program with clear objectives and endpoints. This typically involves blinded, randomized controlled trials in dogs and horses with targeted pain conditions.

- Data Collection & Analysis: Collect comprehensive data on Firocoxib’s safety, efficacy, and pharmacokinetics (drug absorption, distribution, metabolism, and excretion) in the target animals. Ensure statistically significant results to support regulatory approval.

- Regulatory Documentation: Prepare a comprehensive dossier for regulatory bodies like the FDA. This includes detailed information on manufacturing processes, quality control procedures, pre-clinical and clinical trial data, and risk assessments.

- Regulatory Liaison: Maintain open communication with regulatory agencies throughout the approval process. Address any questions or concerns promptly to ensure a smooth and efficient review.

3. Launch & Growth:

- Marketing & Sales Strategy: Develop a targeted marketing strategy that reaches veterinarians and pet owners. This may involve educational materials, attending veterinary conferences, and collaborating with animal health distributors.

- Market Analysis & Differentiation: Analyze the competitive landscape for NSAIDs in veterinary medicine. Highlight Firocoxib’s unique advantages (e.g., targeted COX-2 inhibition, rapid onset of action, minimal side effects) to differentiate it from competitors.

- Distribution Channel Management: Establish a reliable distribution network to ensure Firocoxib reaches veterinary clinics and pet hospitals nationwide. Explore partnerships with distributors specializing in animal health products.

- Cost-Competitive Production: Optimize manufacturing processes to ensure cost-effective Firocoxib production. Negotiating with suppliers for raw materials and exploring alternative manufacturing methods can improve profitability.

4. Maturity & Decline:

- Lifecycle Management (LCM) Strategies: As Firocoxib reaches maturity, explore strategies to extend its market relevance. This may involve:

- New Formulations: Develop new dosage forms (e.g., flavored chewable tablets for easier pet administration) or long-acting injectables for improved convenience.

- Combination Therapies: Explore the potential for combining Firocoxib with other medications for a broader therapeutic effect.

- New Species Applications: Investigate the safety and efficacy of Firocoxib in other animal species (e.g., cats, and rabbits) to expand the market reach.

- Cost Optimization: Continuously evaluate and optimize manufacturing processes to reduce production costs and maintain profitability in the face of potential generic competition.

- Manufacturing Process Improvement: Explore new technologies or more efficient manufacturing methods to improve product quality and potentially reduce production costs.

By carefully considering these factors at each stage, manufacturers can ensure Firocoxib remains a valuable therapeutic option for veterinarians and pet owners throughout its product lifecycle.

Firocoxib Factory: Qingmu Pharmaceutical

Qinmu Pharmaceutical stands as a testament to the company’s dedication to pharmaceutical excellence. Situated in China, this state-of-the-art facility is meticulously designed to produce high-quality Firocoxib Active Pharmaceutical Ingredient (API) to meet global demand. Equipped with cutting-edge technology and staffed by a team of skilled professionals, This Firocoxib factory adheres to stringent quality control measures at every stage of the manufacturing process.

From sourcing raw materials to final product distribution, the facility prioritizes precision and purity, ensuring that each batch of Firocoxib API meets international regulatory standards. With a commitment to innovation and sustainability, Qinmu Pharmaceutical continues to be a trusted leader in the production of Firocoxib API, supporting the development of formulations that enhance animal health and well-being worldwide.